Checkweighing Applications: Interview with Ralf Molls

SysTec's Export Manager Ralf Molls explains checkweighing applications

What are the types of checkweighing applications for which the W&M approved SysTec weighing electronics are suitable?

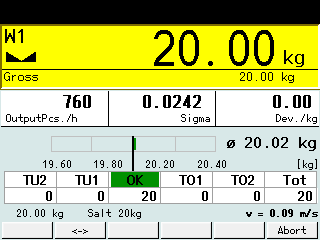

The SysTec weighing electronics are suitable for both, automatic scales for catchweighing (price labeling) and checkweighers with sorting device (for the checkweighing of prepackaged goods). The checkweighers capture weights in quick succession and sort out products with out‐of‐tolerance weights. The approved SysTec weighing electronics have proven themselves in dynamic and static operation and are mainly used in the weighing ranges from 2 kg to 60 kg. The robust and easy‐to‐clean devices are suitable for use in the food industry, the chemical industry and in logistics.

What is special about the CHECK E standard application software ‐ what features do customers benefit from in particular?

The standard CHECK E software covers all relevant legal requirements within the EU ‐ including extensive statistics functions. The filter algorithms used for the determination of the measured values can be optimally adjusted to the weight range of the test objects that are to be weighed, so that a high throughput can be guaranteed.

Apart from stand‐alone operation, the units can also be easily integrated into higher‐level data processing and PLC systems. To this effect, Ethernet and various fieldbus interfaces, such as PROFINET, are available. And of course, the software also offers a remote maintenance option.

Can specific customer requirements be addressed that are not covered by the standard software?

The ability to adapt the application software to customer‐specific requirements is a strength of SysTec. With the powerful programming tool RTC WIN, our customers can either program individual modifications themselves or have them realized by SysTec.

What are the storage options for products?

Product data are stored in a power fail‐safe memory area of the weighing indicator and can be saved, edited and loaded , e.g. via USB stick or PC software.

In addition, data can be transferred to external databases, e.g. via Ethernet.

What is the difference between EASY CHECK and CHECK E software?

The EASY CHECK software is characterized by simplified calibration and startup. The application covers the basic functions of checkweighers, but can only be used in start‐stop mode for applications requiring W&M approval. In the operating mode with dynamic weight recording, the CHECK E software shows its strengths with approved belt speeds of up to 1.2 m/s. CHECK E is W&M approved for automatic checkweighers and automatic catchweighing instruments.

Which SysTec devices can be used for checkweigher and catchweigher applications and why is this hardware particularly well suited?

The IT6000E and IT8000E weighing indicators are used for checkweigher and catchweigher applications. These devices feature a modular design so that the optimum hardware configuration can be chosen for the respective application, e.g. for connection to light barriers or PLC and/or visualization systems.

Due to the inherent free programmability of these units, a wide variety of customer requirements can be accommodated. Also, the use of standard analog load cells provides a unique price/performance ratio. For all customers for whom robustness and cost efficiency play an essential role, analog load cells are more attractive than the sensitive and more expensive digital load cells.

What does SysTec offer to support the commissioning of a checkweigher?

To facilitate easy commissioning, SysTec provides a software plugin for the proven configuration tool IT CONFIGURATOR . The new IT CHECK CONFIGURATOR plugin supports commissioning step by step and calculates the best possible filter settings for dynamic operation. This saves an enormous amount of time during commissioning and gives the personnel on site the certainty that the optimum settings for filters and correction curves have been made.

What trends do you see in checkweigher applications and which new SysTec developments support the new market requirements?

One trend we see emerging in checkweigher applications is the use of remote maintenance. With the new ScaleRemote app, SysTec meets the need of many service technicians for site‐independent visualization and parameter setting.

A big relief for service personnel is also the IT CHECK CONFIGURATOR mentioned earlier. The settings made with this software tool are based on the accumulated experience of commissioning engineers and take into account possible changes of ambient conditions (e.g. changes of belt speed).

This ensures a fast and repeatable commissioning process, which can thus be carried out and documented without expert knowledge.