Weighing indicators for W&M approved checkweighers and catchweighers

Fast Checkweighers. Powerful Catchweighers.

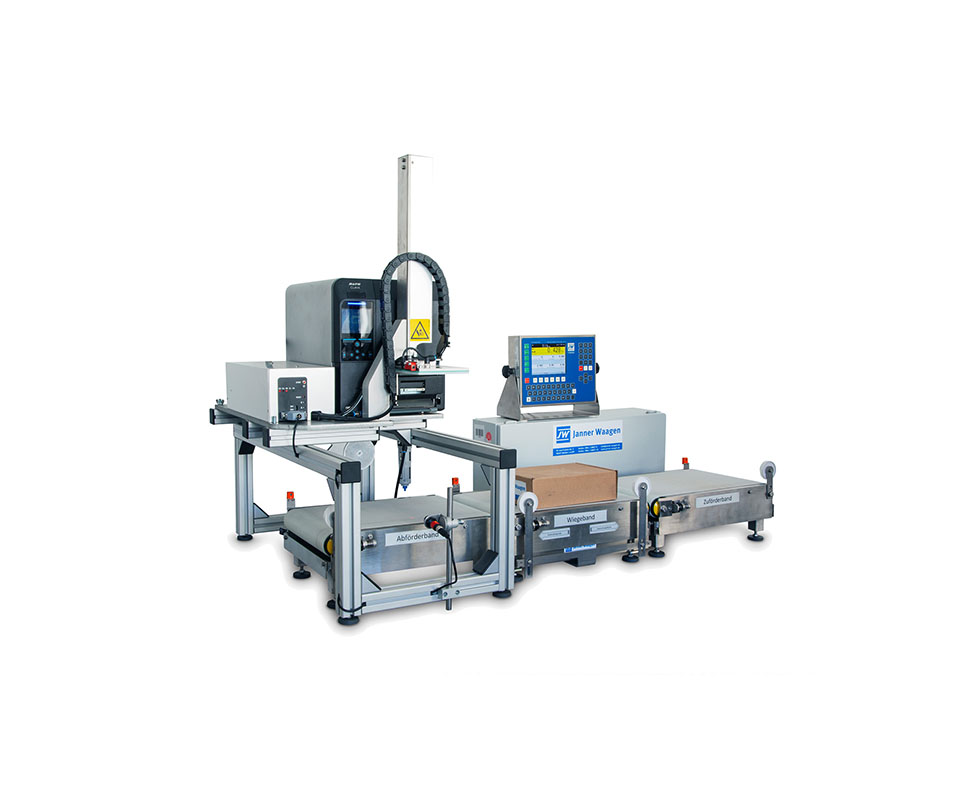

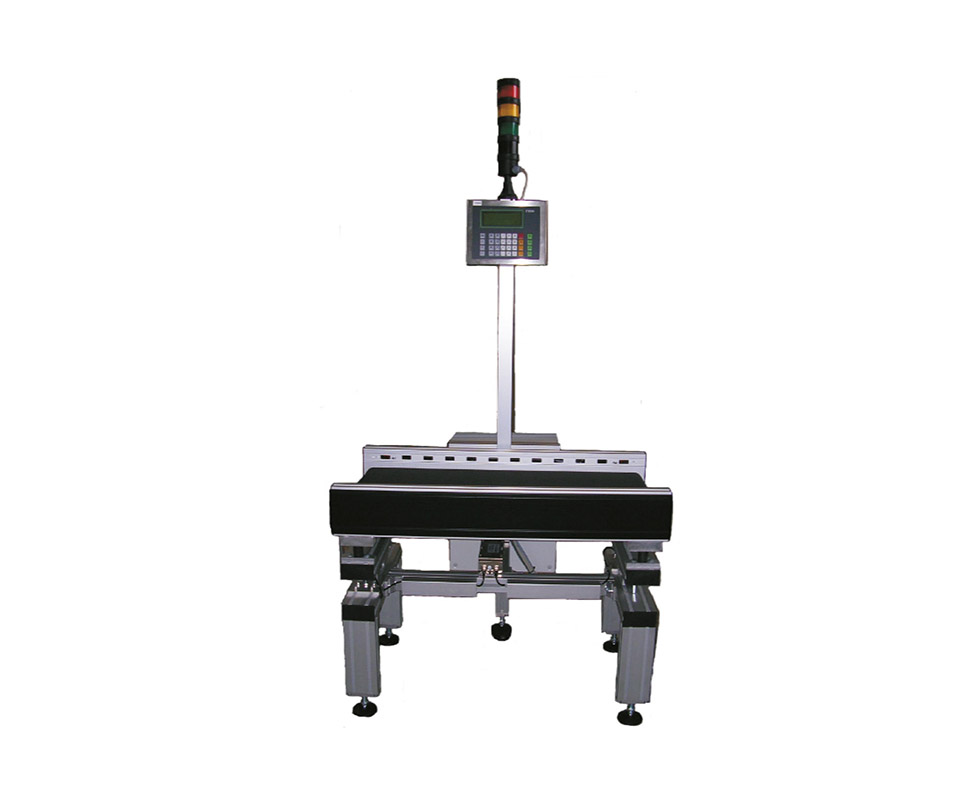

Ideal for check scales: SysTec weighing indicators & controllers are ideal for checkweighers and catchweighers. The W&M approved weighing systems ensure cost effective and secure checkweighing processes by reliably preventing too heavy or too small objects to reach the market. The Weights & Measures approved SysTec weighing electronics allow precise and fast checking of the items' weight, in dynamic mode or start/stop operation.

A pusher – controlled via signal outputs – directly ejects products with the wrong weight. This helps to reduce material waste, accelerate the handling process and meet legal compliance requirements. When used as automatic catchweigher, the SysTec weighing indicators automatically capture the product weight and control the labelling of goods.

The weighing electronic connects to single-point scales or weighing platforms with 4 load cells. Deviations from target weight as well as standard deviation and mean weight are displayed on the color screen. It is also possible to connect to office workstations in order to control the processes of individual checkweighing systems.

SysTec weighing indicators for sample quality controlling (SQC)

Prepackaged goods with nominal quantities of up to 10 kg (l) are subject to sampling according to the national regulations (e.g. FPackV in Germany). SysTec weighing electronics connect to up to two scales to check for weight or volume. The samples are evaluated according to the German regulations for prepackaged goods (FPackV), pharmacopoeia (EU) or freely chosen limits.

This might interest you:

Which weight indicator fits best to your requirements?

7 good reasons for SysTec's weighing electronics

- Simple operator prompting in various languages

- Robust weighing indicators with stainless steel design (IP69K). Ideal for a wide range of check scales

- High resolution weight capturing and fast signal processing ensure fast and accurate sample checking

- Extensive options for data recording, evaluation and memorization

- Simple integration into PC networks or PLC applications via fieldbus

- Versions for the use in potentially explosive area

- Specialist advice and technical support when it comes to checkweighers and catchweighers

Typical fields of application

Checkweighers and catchweighers play a central role in the food, pharmaceutical, and manufacturing industry.

Sampling is required according to national regulations – e.g. FPackV in Germany – when placing goods on the market. The weight must always be determined using an approved control instrument.

| Model | IT1 CHECK | IT3 CHECK | IT6000E EASY CHECK | IT6000E CHECK | IT8000E EASY CHECK | IT8000E CHECK |

|---|---|---|---|---|---|---|

| Manual mode | - | - | - | - | ||

| Weight tolerance check with change of color | - | - | - | - | ||

| Output signals for 'under tolerance', tolerance ok' and 'over tolerance' | - | - | - | - | ||

| W&M approved as automatic catchweighing instrument, with weight storage (start/stop mode) | - | - | ||||

| W&M approved as automatic catchweighing instrument, with weight storage (dynamic mode) | - | - | - | - | ||

| W&M approved as automatic checkweighing instrument (start/ stop mode) | - | - | ||||

| W&M approved as automatic checkweighing instrument (dynamic mode) | - | - | - | - | ||

| Output signals for TU2, TU1, OK, TO1, TO2 zone | - | - | ||||

| Statistics functions with mean value, standard deviation, number of weighings, etc. | - | - | ||||

| Option to adjust the mean value to the batch target | - | - | - | - | ||

| Article / product file | - | - | ||||

| Dynamic reading of weight | - | - | ||||

| Automatic mode | - | - | ||||

| Pusher control | - | - | ||||

| Operation with light barriers | - | - | ||||

| Fieldbus interface | - | - | - | - | - | |

| Custom-specific modifications | - | - | ||||

| Alphanumeric keyboard | - | - | - | - | ||

| Analog control of belt speed | - | - |

| Model | IT6000E SQC | IT8000E SQC |

|---|---|---|

| W&M approved | ||

| Number of scales | 2 | 2 |

| Check in accordance with regulations for prepacked goods, pharma (EU), free | ||

| Check by weight / volume | ||

| Samples single, additive, 2-step | ||

| Tare average / individually | ||

| Recording printer / host / file | ||

| Number of simultaneous checks | 50 | 50 |

| Product file | 250 | 250 |

| Additional check criteria | 8 | 8 |

| Alphanumeric keyboard | - |