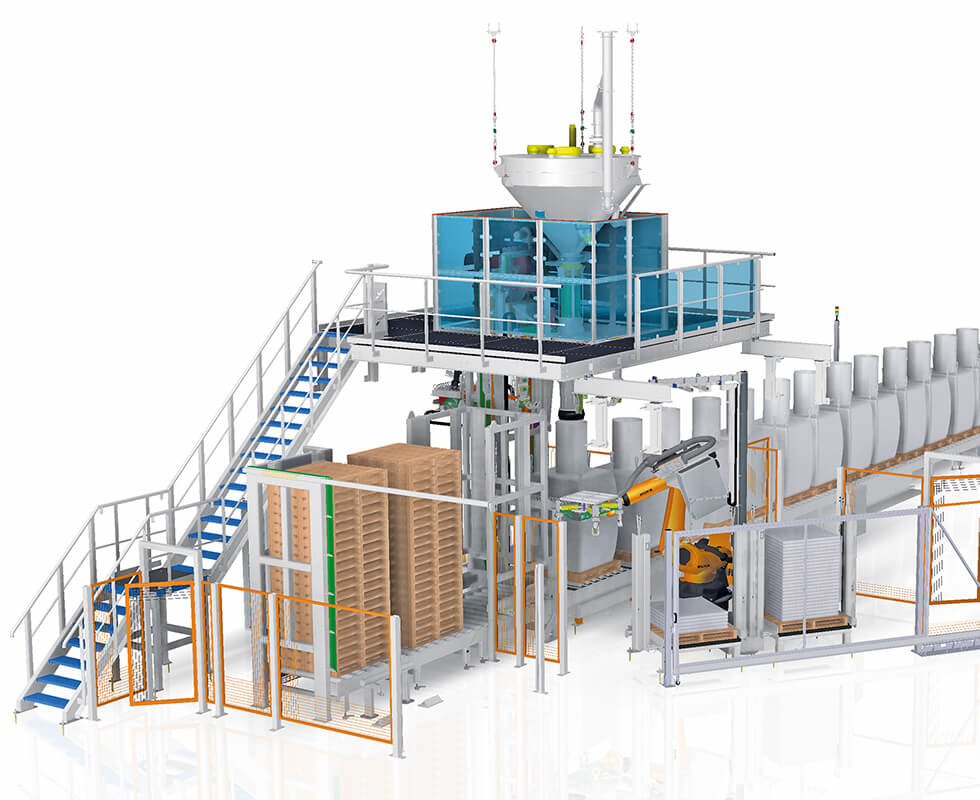

Fully automatic big bag filling station for cristobalite

High throughput with W&M approved SysTec weighing indicators

When it comes to filling raw materials into big bags, high throughputs are crucial. Therefore, SIBELCO uses a fully automatic EMDE station for cristobalite filling with a W&M approved SysTec weighing indicator IT8000E.

The key facts

- 40 filled big bags per hour

- 1200 kg net weight per big bag

- W&M approved weighing electronics

- Recipe management via PLC

- Fast implementation of the fully automatic filling station by EMDE

In Dessel, Belgium, SIBELCO operates the fully automatic filling station for cristobalite - designed and installed by the plant manufacturer EMDE within a short period of time.

Thanks to the powerful weighing and control technology, up to 40 big bags can be filled per hour. Each big bag has a net weight of 1200 kg. To ensure the legal for trade requirements of the filled bags, the W&M approved SysTec weighing indicators are used. EMDE has been installing SysTec‘s innovative weighing systems and controllers on demanding filling lines for many years.

To optimize the performance of the filling station, a weighed hopper was installed above the filling station to discharge the cristobalite into the big bag. This allows simultaneous filling of the container above during the big bag handling times.

Customer benefits

- Reliable automatic operation saves time and resources

- W&M approved fillings via precisely operating batching systems

- High throughput - fast and highly accurate weighing technology

- Control systems configured according to customer requirements

- Optimal big bag filling and stability via compaction system

- Automatic closing for dust & emission protection

- Automatic release and labeling of the filled big bags

- Connection to MES system (Manufacturing Execution System) for monitoring purposes

The customer

SIBELCO is a global materials solutions company. As a diversified industrial minerals group, SIBELCO sources and transforms a wide range of minerals and is a leader in glass recycling. These include, for instance, silica sand, feldspathic minerals, olivine and clays. With over 114 production sites in more than 30 countries, SIBELCO employs more than 5,300 people worldwide.

Cristobalite - the material to be filled

Cristobalite is a high-temperature modification of quartz and occurs only very rarely in nature. For this reason, cristobalite is produced synthetically for industrial purposes from pure quartz in a rotary kiln at approx. 1500 °C. Main applications of cristobalite are dispersion-bound exterior paints and plasters, dental impression compounds, artificial marble or countertops.

![[[Translate to "English"]] Logo SIBELCO [[Translate to "English"]] Logo SIBELCO](/fileadmin/public/Redaktion/Bilder/Waagen-Insights/SIBELCOlogo.png)