Dynamic truck scales

Scale manufacturer BATSCH uses SysTec weighing electronics for Weigh-in-Motion systems

Unique in the world: The Austrian company BATSCH is considered an innovation driver of dynamic truck scales for heavy vehicles. SysTec weight indicators / terminals IT8000E and IT6000E are used in the W&M approved dynamic truck scales patented by BATSCH.

These Weigh-in-Motion systems are a milestone in vehicle weighing and have been nominated for the Austrian State Award "Designing Mobility Safely" - the most important award of the Austrian Federal Ministry of Transport, Innovation and Technology (BMVIT).

Successful in operation: These systems, which are unique in Europe, were installed by the Austrian executive at the traffic control station on the Austrian A5 northern freeway to monitor traffic safety. The operation of the measuring system has been in successful continuous operation since 2018.

The key facts

- Automatic overload detection while driving over the scale

- Up to 35 km/h travel speed

- Legal-for-trade system and automatic scale

- Accuracy: +/- 1 percent

- Total weight determination up to 100 t and axle loads up to 20 t

Benefits of the new dynamic truck scales

Increased road safety through in-motion weight check: Fewer accidents due to overloaded trucks

Reduction of economic costs through reduced road damage caused by overloaded vehicles

Uninterrupted and automatic checking of weight and axle loads while on the road

W&M approved and legally enforceable weighing result is submitted to EDP in realtime

In case of overloading, fines can be levied directly

The fast weighing procedure enables a higher monitoring frequency

The requirements of EC Directive 2015/719 are fully met

Weighing systems increase traffic safety

Overloaded trucks are a danger for all road users. The driving stability of the vehicles is impaired, thus increasing the risk of accidents. In addition, damage to roads and bridges is inevitable. For this reason, truck scales are extremely important as control instruments when it comes to safety and reducing economic costs.

With classic static truck scales, the police wave suspicious trucks out of traffic and then check them on a scale. Although the static method provides precise measurement data, it is time-consuming, cost-intensive and only allows random checks of a few vehicles. Therefore, the new dynamic BATSCH drive-over scales are of great advantage, as they allow fast and complete W&M approved monitoring.

Monitoring of axle loads: EC Directive

According to EC Directive 2015/719, in 2021 EU member states must introduce measures for the detection of vehicles that exceed the permissible axle loads or total masses. This includes weighing systems integrated into the infrastructure (roads) as well as on-board systems in the truck.

Patented world novelty

The scale manufacturer Hans Batsch has a long-standing partnership with the weighing terminal manufacturer SysTec. Both companies have always been engaged in innovations in the field of weighing technology.

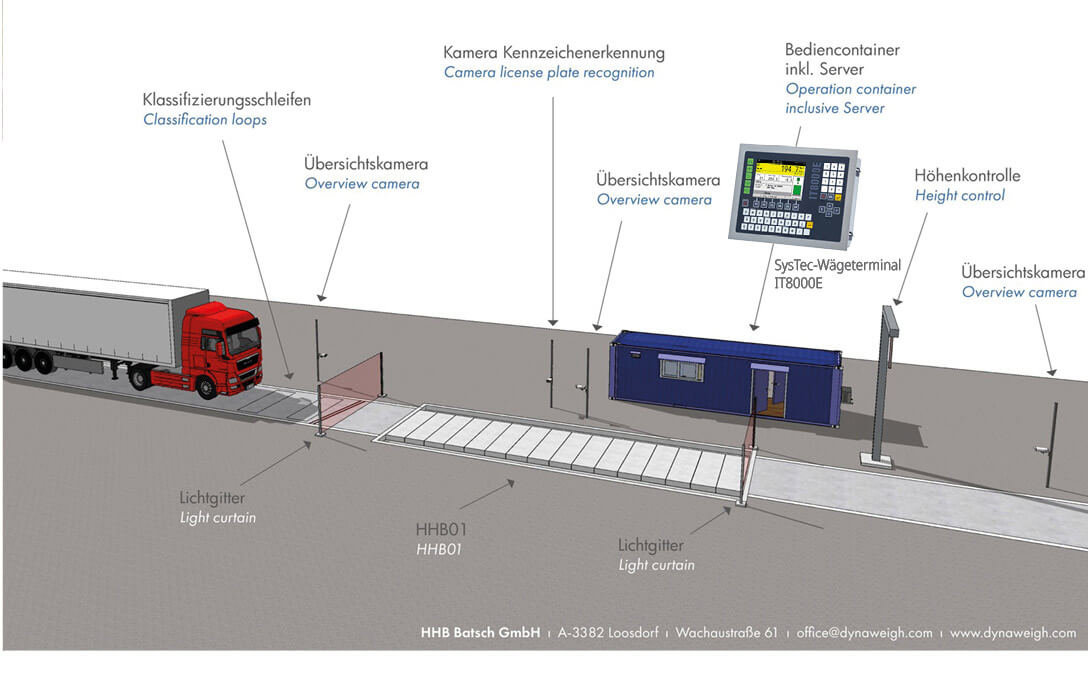

What started as a research project of the BATSCH company, after years of intensive development work, now resulted in two patented W&M approved dynamic truck scales with integrated SysTec weight indicators. BATSCH sells the weigh-in-motion systems under the brand name "Dynaweigh". Weighing takes place dynamically in fully automatic operation without the intervention of operating personnel. In doing so, the vehicle drives over all weighing modules of the weighbridge and the weight is automatically captured, recorded and stored in the approved weight memory. The innovative scales can eliminate vibrations through intelligent software and absorb large longitudinal and transverse forces, such as those that occur when a vehicle drives over a weighbridge at higher speed.

The forces are recorded at several measuring sensors and analyzed by means of special software. The software filters out the dynamic oscillating forces and calculates the actual vehicle weight. The weighing systems are characterized by an accuracy of +/- 1 percent and record vehicle weights at a travel speed of up to 35 km/h. It is possible to generate a weighing report in about six seconds and link the weighed truck with a photo and automatic license plate recognition. This enables seamless and legally enforceable monitoring of heavy trucks, even at peak times on the highway.

BATSCH truck scales have been successfully tested for calibration class 2 by the Federal Office of Metrology and Surveying and are approved in Austria and Germany. Approvals for further countries are pending.

The weighing electronics

The evaluation unit consists of a network of several SysTec weighing terminals, which in a coordinated manner and independently of each other determine partial results of the displayed weights.

To display the total weights, a front-end device is used, which calculates and allocates the partial results.

For operation from a second operator station, another SysTec weighing terminal can be connected to the front end, which mirrors the display and operation of the front end 1:1 and can be used as a remote control unit.

Black boxes

SysTec's black boxes include the weighing electronics, but without display and operating unit. They are equipped with two analog/digital converters of type ADM for the connection to scale platforms with strain gauge load cells.

Technical data of the ADM

- Max. 8 strain gauge load cells 350 Ω each

- Range of load cell impedance 43 Ω to 4500 Ω

- W&M approved resolution of 6000 d at max. 80 % preload, internal resolution 524,000 d

- Smallest permissible input signal for W&M approved applications 0.33 μV / d

- Update rate 1,200 updates per secSupply voltage for load cells: 5 V ± 5 % (gated power supply)

The black boxes communicate with the front end device via network (TCP/IP).

"The variety of applications in the scale and software sector requires continuous innovation and ongoing development in order to maintain and further expand the market position already achieved! Therefore we use smart and W&M approved weighing terminals from SysTec, as they can be flexibly adapted to our own requirements."

Hans Batsch, Managing Director BATSCH Waagen & EDV GmbH & Co KG